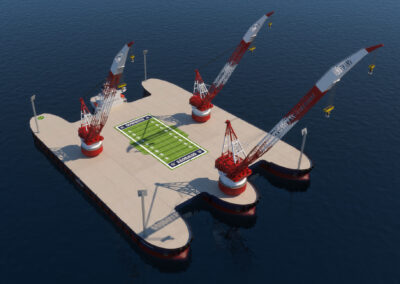

OCEANDOCK LX

Redefining offshore wind turbine installations around the world.

Windthrust has developed a new safe and secure technology that will redefine offshore wind turbine installations around the world – The Oceandock LX. The Oceandock is a 60,000m² self-propelled floating port and installation vessel for Substations, Monopile Foundations and Wind Turbine Generators.

Principal Particulars:

- Overall length: 292m

- Beam: 215m

- Deadweight: 500,000 tonnes

- Weather deck loading strength 25 tonnes m² or as specified by the client.

Key Features:

- Ballastable

- Self-propelled, easily movable to different locations using its own propulsion units.

Equipped with:

- Dynamic positioning capability for precise manoeuvring and positioning.

- Two tugs for assisting with the berthing of feeder ships delivering wind turbine components.

- Two boom lifts for assisting with the installation and assembly of wind turbine generators.

- Two 2,600 tonne cranes

- One 6,000 tonne crane

The three cranes can cover every square metre of the 60,000 square metre deck and can operate independently and simultaneously with different tasks.

The 6,000-tonne crane can safely position a 6,000-tonne substation topside in one single lift.

Currently two or more installation vessels are required to install each turbine. The Oceandock offers a safe, practical, and cost-effective alternative to current systems such as jack-up vessels which are inadequate and far too small. Jack-up vessels can only carry 3 to a maximum of 6 wind turbine generators, therefore once these are installed, the vessel must return to port for reloading. The Oceandock is not required to return to the port for reloading.

The Oceandock simultaneously unloads wind turbine components from feeder ships, assembles and installs complete wind turbine generators, substations and monopile foundations.

The assembly of the wind turbine generators take place at near deck level; making it possible for the complete wind turbine generator units to be placed in position in one single lift, making this operation safer and faster.

Advantages

- Large (60,000 m²) clear deck floating port and supply base.

- Safe installation for wind turbines generators of any size.

- The location of wind farms is not limited to near shore.

- It can be positioned and operate in any water depth.

- Easily accessible by any type and size of feeder vessels.

- The secure and stable 500,000 DWT Oceandock LX can accommodate over 100 persons

- Reduction of the supply chain, time, costs, and risks.

- Scalable – The size of the Oceandock LX can be customised.

- The Oceandock LX can safely operate in 8 metres wave height.

- Minimises footprint in sensitive coastal areas.

- Capital effective mobile port infrastructure.

- Safe and secure docking facilities for multiple vessels.

- Reduction of supply chain costs and risks.

- Rapidly deployed in any part of the word.

- Alternative applications across industries.

- Economy of scale, an entire field of offshore wind turbines generators can be stored, assembled and installed.

- It can be purchased or chartered

- One-stop service.

Key Benefits

- Zero on-shore port cost – No land is required ashore for storage and pre-assembly of wind turbine generators.

- Zero costs for onshore equipment (e.g. cranes, forklifts etc.) for pre-assembly of wind turbine generators.

- Zero onshore port fees for feeder vessels bringing wind turbine generator components.

- Zero onshore port fees for current wind farm installation vessels; these vessels will NO longer be required.

- Zero stevedoring costs at the onshore port for unloading feeder vessels bringing in or re-loading wind turbine generator components.

- Zero shipping costs from the on-shore port to the wind farm and dead-time voyage back to the o-onshore port for reloading.

- Reduction of handling operations and costs by delivering the wind turbine generators components direct to the Oceandock LX.

- The Oceandock LX will generate more than 50% savings on current costs.